Product > Flat Bed > Cutting Rules

![]()

Dieflex Cutting Rules

Sandvik Dieflex, the world’s first edge hardened cutting rule, combines the two contradictory requirements of good bendability and high wear resistance.

Sandvik Dieflex, the world’s first edge hardened cutting rule, combines the two contradictory requirements of good bendability and high wear resistance.

Since its introduction, Sandvik Dieflex has been further enhanced with improvement in tolerance, bendability and a dry rust protection coating.

It is only through continual upgrading and consideration investment in research and development that Sandvik Dieflex maintains its position as a market leading brand.

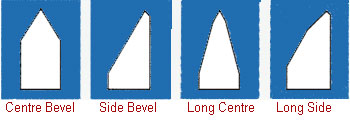

Dieflex is available in the following forms :-

![]()

|

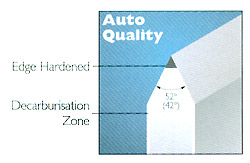

Dieflex Auto

Dieflex Auto has been speciafically developed as a manufacturing process for the production of rules that are ideally suited to diemakers working with automated rule processing and bending equipment.

Side face decarburization of the rule gives the benefit of a soft ‘tensile' skin for excellent bendability. The edge hardening of the rule gives high wear resistance.

Dieflex Auto also offers tight height, straightness and thickness tolerances, minimum coil set and closely controlled hardnesses giving the benefit of smoother running on automatic machinery.

![]()

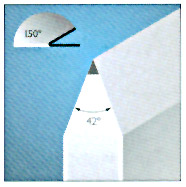

Dieflex 52

|

The original Dieflex rule with its 52˚ cutting edge. The ideal combination of edge hardness and

flexibility for diecutting a wide range of materials.

The well controlled decarburisation allows a 2 point rule to be bent to a minimum of 150˚.

| Point Sizes: | 1 ½, 2, 3 and 4. |

| Heights: | Up to 100mm |

| Availability: | Coil and metre lengths. |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC) 3pt/4pt Body – 340HV (35HRC) Edge – 640HV (57 HRC) |

| Applications: | For solid and corrugated boards and all commonly used substrates. |

![]()

Dielefx 42

|

The 42˚ angle requires less cutting pressure which leads to a longer cutting life.

The sharp cutting angle achieves easier penetration of the substrate thereby reducing slivers, swarf and dust. A 2 point rule can be bent to a minimum of 150˚.

| Point Sizes: | 1 ½ , 2, 3 and 4. |

| Heights: | Up to 100mm |

| Availability: | Coil and metre lengths |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC) 3pt/4pt Body – 340HV (35 HRC) EDGE – 640hv (57 HRC) |

| Applications: | Particularly suited to paper board and recycled board with high dust content. |

![]()

Dieflex Hard

|

A rule with all the Dieflex features but ith a harder body.

It is ideal for use with dies that require less tight bends, but where greater body stability is essential.

Dieflex Hard will stand up to the toughest of substrates.

| Point Sizes: | 2, 3 and 4. |

| Heights: | Up to 100mm |

| Availability: | Coil and metre lengths |

| Hardness: | Body – 400HV (41 HRC) Edge – 640HV (57 HRC) |

| Applications: | Suited to solid and corrugated board, plastics and dense substrates. |

![]()

Dieflex Superbend

|

A slightly lower edge and body hardness gives greater bendability – up to 160˚.

Dieflex Superbend is the ideal rule for the production of more intricately shaped dies.

| Point Sizes: | 2 |

| Heights: | Up to 23.80mm |

| Availability: | Coil and metre lengths |

| Hardness: | Body – 330HV (33 HRC) Edge – 620HV (56 HRC) |

| Applications: | Particularly suitable for greeting cards, tickets and presentation work |

![]()

DieHard

|

A rule with a hard and stable body and with good bendability.

A higher edge hardness facilities the cutting of difficult substrates.

| Point Sizes: | 2 and 3 |

| Heights: | Up to 50mm |

| Availability: | Coil and metre lengths |

| Hardness: | Body – 470HV (47 HRC) Edge – 680HV (59 HRC) |

| Applications: | Ideal for cutting the more difficult substrates, such as plastics and PVC. |

![]()

Diehard 700XD

|

The 42˚ angle with deep edge hardening gives increased wear resistance.

The edge hardness is 50% as deep again as Sandvik Dieflex rule, giving significant increases in die life on most applications.

| Point Sizes: | 2 and 3 |

| Heights: | Up to 50mm |

| Availability: | Coil and metre lengths |

| Hardness: | Body – 400HV (41 HRC) Edge – 720HV (60 HRC) |

| Applications: | For cutting abrasive materials such as gaskets and plastics. |

![]()

Dieflex Ultra

|

Available with both 42˚ and 52˚ edge, its friction reducing coating gives easier penetration into the substrate.

The cutting edge remains sharper longer.

Gives consideration make-ready advantages, avoids costly downtime and reduces slivers and dust.

| Point Sizes: | 2,3 and 4 |

| Heights: | Up to 100mm |

| Availability: | Coil and metre lengths |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC) 3pt/4pt Body – 340HV (35 HRC) Edge – 640HV (57 HRC) |

| Applications: | A rule for solid and corrugated board. Ideally suited to food, pharmaceutical and medical packaging. For long runs with reduced swarf contamination. |

![]()

Dieflex – GR

|

Dieflex – GR has a fine ground edge that is particularly suited to cutting more difficult materials.

The ground edge of the rule has the distinct advantage of requiring reduced cutting pressure when used with more demanding substrates.

| Point Sizes: | 1 ½ 2, 3 and 4 |

| Heights: | Up to 100mm |

| Availability: | Coil and metre lengths |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC) 3pt/4pt Body – 340HV (35 HRC) Edge – 640HV (57 HRC) |

| Applications: | Achieve a clean, shearing cutting action with laminated or fibrous substrates. |

![]()

Dieflex – G12

|

A rule for even more demanding materials such as brittle plastics.

The very fine ground edge gives improved bendability compared with the standard ground edge rule. The extremely sharp edge means that less cutting pressure is requires.

There is also the benefit of reduced slivers, swarf and dust.

| Point Sizes: | 1 ½ 2 and 3 |

| Heights: | Up to 100mm |

| Availability: | Coil and metre lengths |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC) 3pt/4pt Body – 340HV (35 HRC) Edge – 640HV (57 HRC) |

| Applications: | For more difficult substrates such as laminated plastics, foils, coated/varnished cardboards and polyester. |

![]()

DieHard Xtreme

|

An extra fine ground rule with a sharp edge and a hard stable body. It had good bendability.

The high edge hardness and deep edge hardening, reduces edge wear and gives a longer rule life.

It is ideally suited cutting difficult materials.

| Point Sizes: | 2 and 3 |

| Heights: | Up to 50mm |

| Availability: | Coil and metre lengths |

| Hardness: | Body – 470HV (47 HRC) Edge – 680HV (59 HRC). Deep edge hardened. |

| Applications: | For more difficult substrates such as PET (Polyethylene Terephthalate), plastic materials, laminated boards and more difficult or tough materials. |

![]()

Dieflex Brite

|

A rule with a bright, mirror finish and extremely sharp cutting edge that's suited to the most demanding materials.

The very smooth edge gives improved bendability, reduces friction during cutting, requires less pressure and keeps dust to a minimum.

| Point Sizes: | 2 and 3 |

| Heights: | Up to 50mm |

| Availability: | Coil and metre lengths |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC). 3pt Body – 340HV (35 HRC) Edge – 640HV (57 HRC) |

| Applications: | Suitable for solving dust problems with paper board and recycled board, plastic laminated paper board, resin coated paper and metallized polyester. |

![]()

Diehard Razor

|

This rule has a bright mirror-like and extremely sharp cutting edge. It is deep edge hardened and has a hard stable body with good bendability.

The extreme 30 edge angle makes it the sharpest rule in the Sandvik product range – it is particularly suitable for cutting hard, thick as well as thin materials.

| Point Sizes: | 1 ½ and 2. |

| Heights: | Up to 50mm |

| Availability: | Coil and metre lengths |

| Hardness: | Body – 470HV (47 HRC) Edge – 680HV (59 HRC). Deep edge hardened. |

| Applications: | For cutting electronic panels. PET (Polyethylene Terephthalate) plastic sheets, plastic laminated paper and speciality graphic materials. |

![]()

Dieflex MicroNik

|

Pre-microscopically nicked cutting rule, combines the proven benefits of Dieflex with the advantages of precise micro-nicking. MicroNik makes conventional nicking obsolete. It cuts with less pressure, creates a superior product edge appearance, optimizes hold strength and increases press speeds.

‘Nick' spacing-Standard 4 per 1” and 8 per 1”.

Specials to order.

| Point Sizes: | 2 |

| Heights: | Up to 30mm |

| Availability: | Metre lengths |

| Hardness: | 2pt Body – 380HV (39 HRC) Edge – 640HV (57 HRC). |

| Applications: | Particularly suitable for solid, laminated and coated boards. |

![]()

Dieflex Hard High

|

A rule specifically developed for the plastics industry.

The 400 HV body gives good rigidity yet decarburization provides excellent bendability and it is edge hardened for increased rule life.

It is available with shaved or ground with shaved or ground edges in all edge configurations.

| Point Sizes: | 3 and 4 |

| Heights: | Up to 100mm |

| Availability: | Coils and lengths up to 2 metres. |

| Hardness: | Body – 400HV (41 HRC) Edge – 640HV (57 HRC). |

| Applications: | Ideal for clean, deep cutting of plastic packaging or vacuum formed packaging. |